WEIGHCLEAN

Weightometer Cleaning System, Wet / Dry

The system is built with reliability and safety in mind to meet stringent mine site requirements. It is able to wash unwanted product or debris from on and around a weigh frame, its components or other critical infrastructure.

The system is adjustable to suit the specific installation challenges posed by each site and weightometer.

Customisation of construction material, amount and placement of valves/nozzles is available to suit the needs of each installation / Stainless Braided signal lines / Nitrogen / Air / Water flush liquids.

Remote Command And Control

24v Digital IO Control signals

Autonomous operation

Able to autonomously wash down belt weighing devices during down time

Accepts weightometer input to prevent washing during critical operations

High safety standards

Industry leading, sirens and alarm lights for remote operations

Adjustable to suit site requirements

Various isolation and lockout locations

Mechanical barriers and signage available

Reliability

No moving parts

No electrical solenoid wires under the conveyor or strategic equipment

Filtration with optional auto clean filtration

Stainless Steel pipe work ring main

Low EMF interference to other equipment

High Flow Spray Nozzles

EPDM (Ethylene Propylene Diene Monomer Rubber) nozzles are fast and easy to replace should they be damaged or fouled by debris They are mounted on twin adjustable fittings giving a wide range of location and attitude control.

There are three variations that can be used, duck foot , pig’s tail and cobra head. The one in the illustration is the cobra head.

Hydraulically Controlled Valves

Pressure Regulated flow control valves operate using process mine water and are controlled via filtered signal water feed from our control panel. These have minimal working parts. They can be repaired and or replaced easily with unions either side of the valves.

It can be serviced in situation as it is accessible when diaphragms need replacement

The control circuit pipes can be upgraded to braided stainless steel.

Control Panel

Specifications and Features

Made from 1.5mm 316 stainless steel

Sloped roof prevents build up of fluid/product

Top and bottom flange to easily mount against a wall

Fully welded construction - IP66 rating

Door earthed to cabinet via earth studs

Polyurethane door seal

2mm white powder coated galvanised steel gear tray included

2 x Wiring Loom Z-brackets included for cable management across door hinges

Folded lip/gutter to ensure effective door seal

Door fitted with 2-bit stainless steel locks

316 stainless steel provides a higher corrosion resistance. This makes 316 stainless steel more desirable in applications where powerful corrosives or chlorides are an issue. The benefits of 316 stainless steel include lasting longer than 304, providing you with extra years of life and usage that will retain an attractive, clean finish.

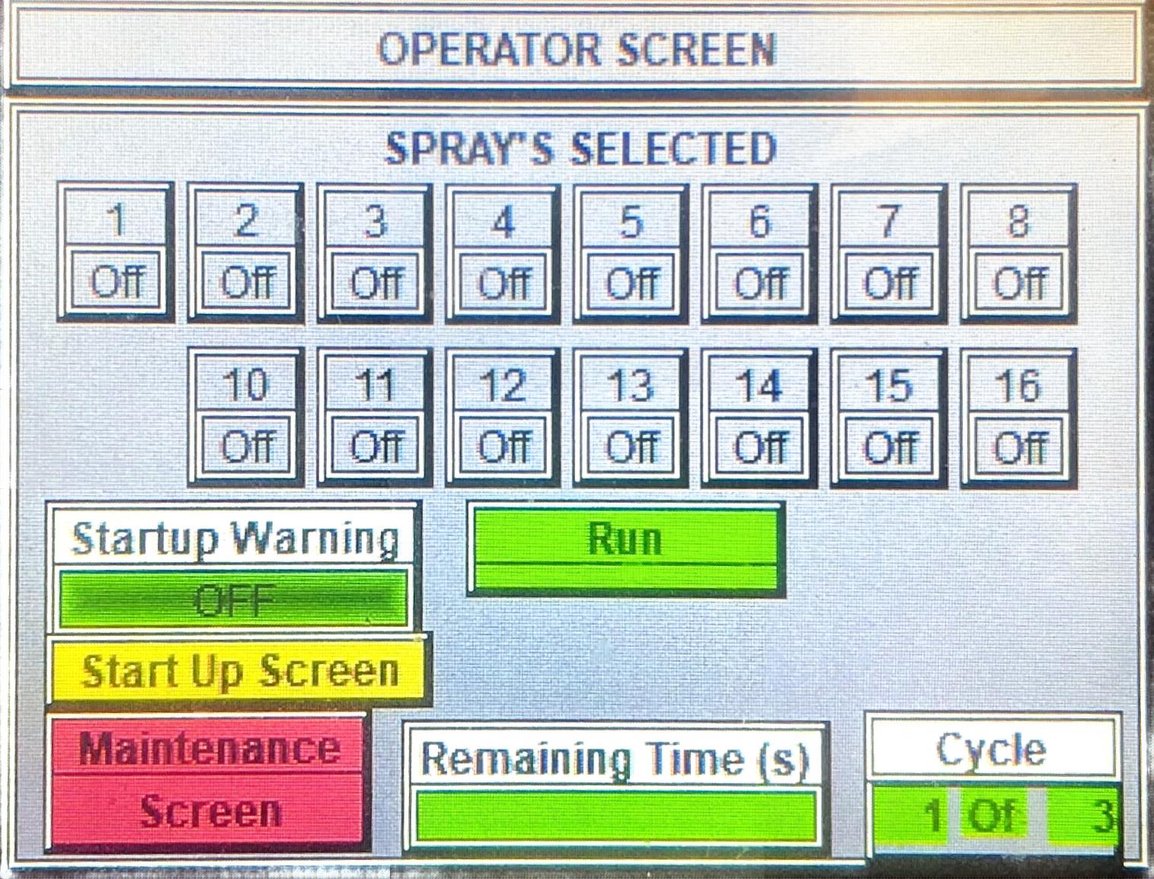

Touch Screen Control Interface

The System comes equipped with a touch screen display that can be used to modify the valve sequence and run time. It also enables trouble shooting and maintenance as well as the ability to isolate individual valves.

These interfaces are interchangeable if they fail and can be programmed prior to instal so in effect are plug and play.

Warning System

There is a warning system to alert personnel that the cleaning process is going to commence. It consists of a red, green and blue light with a siren.

Red Light - the system is being activated so cleaning is imminent

Blue Light - Indicates the system is functioning and water is being sprayed

Green Light - Safe state and the system is idle

Safety Feature

Main line water flow can be controlled buy the system and only pressurises when a wash activation signal is received either locally or remotely

This system is designed to expose any damage or fault by allowing water to flow as opposed to a hidden system where faults are not detected or obvious.

Emergency stop - Shuts the system down and isolates the main line optional valve is installed when fitted

Main valve isolation point is lockable so can be isolated and included in isolation protocols

When the control circuit pipes break you will have a visible leak.

If the valves loses a signal it becomes an open circuit and allows free flow through the valves. This is because they are in a N/O state and it is the pilot pressure that closes it off.